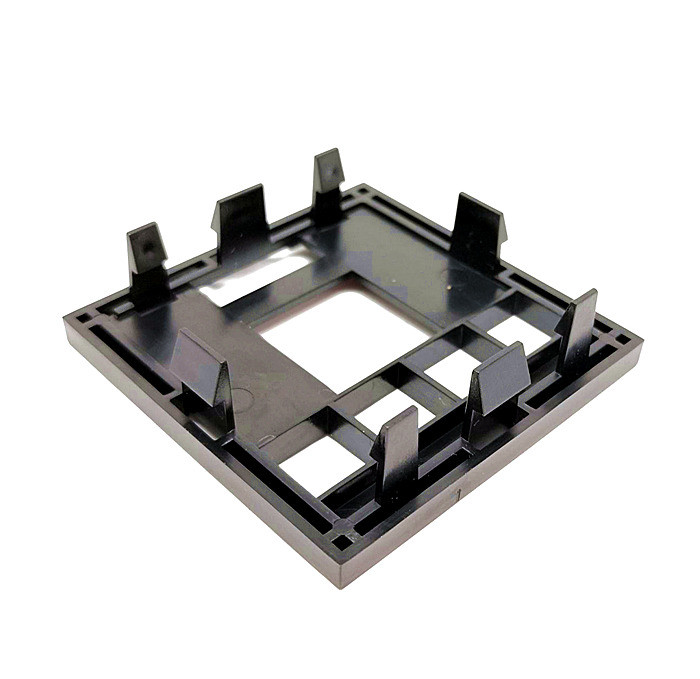

PA66 Electronic Injection Mold

Product Details Description

| Main Product |

CNC Milling, Plastic Mould/Tooling, Prototype,Injection Molding Product, Injection Foaming Mold, 3D Printing,Die Casting, Gas Assisted Injection Molding such as part for Auto, Medcial, Aerospace, Houseware… |

| Mould Base |

LKM Standard, HASCO Standard Self-made, etc. |

| Mould Material |

P20/718/738/NAK80/S136/2738/2316/H13, etc. |

| Moud Precision |

+/-0.01mm |

| Mould Life |

50-500K shots |

| Mould Cavity |

Single cavity, multi-cavity |

| Runner System |

Hot runner and cold runner |

| GateType |

Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

| Equipment |

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic part |

| Plastic Material |

PA6,PA66, ASA, POM, PPS, ABS,ABS+GF,ABS+PC,POM(Derlin),PP, PE,PC,PMMA(Acrylic),PVC,PEI,PBT,PTFI |

| Metal Material |

Aluminum (6061,6063,7075...),Brass, Copper, Brass,Satinless Steel(301,302,303,304...) |

| Surface Treatment |

Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

| Pls Provide |

2D, 3D, samples, or the size of the multi-angle pictures |

| Quanlity System |

ISO 9001: 2019 |

KYE Mold Technoloy Limited is a company with full capacity to make mold and molding for plastic and die casting product, was founded at Chang`an Dong Guan, Guang Dong, China.Over the past years, we've been committed to providing varied molds and injection molded parts for our customers in high quality with short lead time.

KYE sets the difference by diversity with the capacity in manufacturing tools range from large, middle to small size. KYE is an innovative and dynamic team with more than 10 years of experience.This team is at your service offering professional expertise, flexibility and accuracy in assumed deadlines. We are the objective to arrive together with success to the target.

1.Product design

a. We can develop new products based on samples or prototypes by using reverse engineering,3D digitizing and laser scanning technology.

b. We can develop new products according to simple sketch and brief description like function.dimension etc.We provide customers with 3D model and 2D as request.

c. We can join in the customer’s design group. for example: summit the economic plan to save cost.point out the existing design problems for product such as the undercut.sharp angle .processing difficulty and so on.

2.Mold-flow analysis

This is a very important process,because we need to understand the possibility of product in advance in order to prevent some possible problems like air trap.mark.and welding line etc. especially for the big product,so we introduce the advanced moldflow analysis software and professional engineers to stimulate ,analyze ,optimize and validate plastic parts and mold design .it effectively pre-prvent the potential problems as so to save cost ,control quality and guarantee delivery time.

3.prototype-making

For some projects,Prototype is inenvitable process.it can help engineer check the product function and also prevent some problems which should be found after mould trial. In order to meet the requirement,we bought the advanced prototype equipment and cultivate the high-skill staff to do the prototype by CNC or laser machine . As a result ,it can help us provide customers with high-quality prototype for confirmation very fast.

4.Injection

Horinzonal injection machine

vertical injection machine

Double colour rotary machine with air and robot assist injection machine

5.second –Processing

Spray painting

Pad printing and silkscreen printing

Engraving

Assembling

Our Advantage

1. Owned mold making workshop

KYE has owned mold workshop with 15 CNC machine,10 EDM, 4 wire cutting,milling machines, drilling machines, 2CMM and 3CMM in house to make sure the high quality and lead time.

2. Professional Engineer team

10 year of full expereience engineer team can offer you the best solution for the project and help you manage the project in the best effective way.

3. Various Service

We offer various service including Automotive parts, Home Appliance, Electronic and Medical parts with one stop service

including product design, mould fabrication and second processing,such as Spray painting,Printing, Chrome, Engrave and assembling,etc.

4. Injection molding workshop

KYE has around 40-50 sets of injection machine range from 50T to 600T.

RAQ

Q1: Does your company make mold by yourself?

A: Yes, we have our owned mold workshop around 2,000 square meters including mold and molding.

Q2: What is the software you use for design and mold making?

A: We usually use UG, PROE, CAD, CAD/ProE/UG/SOLIDWORKS for mold 2D and 3D design.

Q: How you do the quality control?

A: we have system quality control process

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.

Q: How to pack the moulds and products?

A:

1). For moulds, we will be coated one-layer anti-rust oil first,and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!